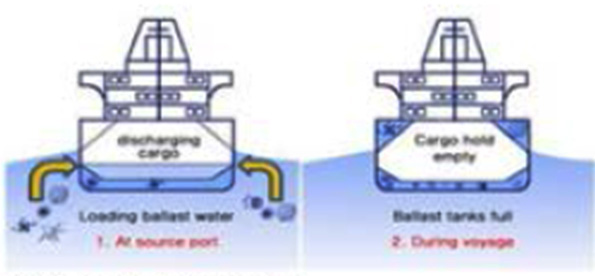

A change in the ecosystem balance caused by the ballast water

Loading: Sea water charged

(Harmful aquatic organism got intol)

Unloading: Sea water discharged

(With Harmful aquatic organism as well)

At any one time ballast water can naturally contain an estimated 7000 different species of organisms comprising of plankton, bacteria and viruses.

Once discharged some species can withstand a wide range of environmental conditions and may not have natural predators. In such cases these organisms can become invasive species causing a change in the ecosystem balance. y each year. These ’nonnative species’, if they become established, can have a serious ecological, economic and public health impact on the receiving environment.

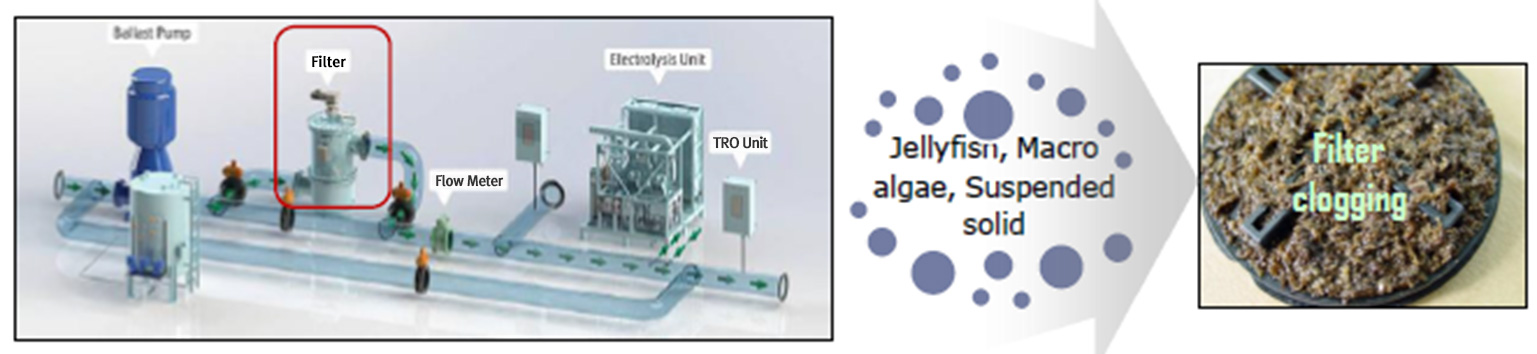

Disadvantage of current BWMS

Filter products for existing marine equilibrium water treatment devices cause clogging, resulting in failure of shutdown

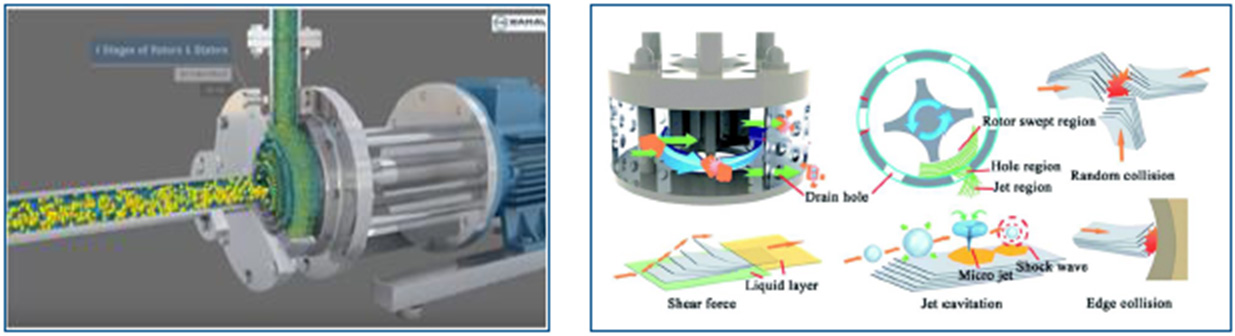

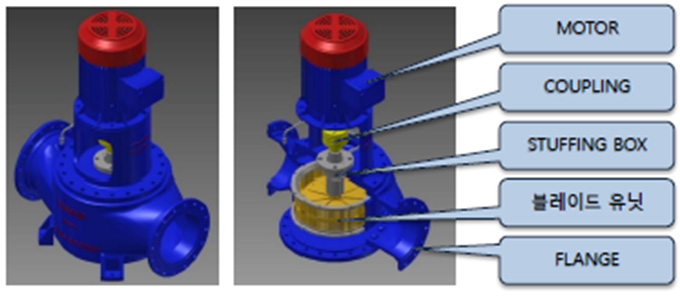

Solution – Physical Treatment System(PTS)

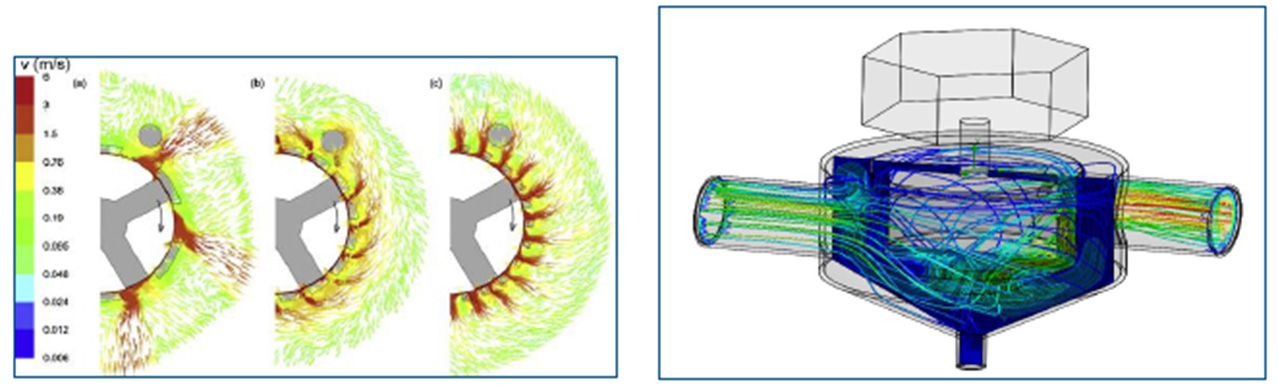

- When the aquatic organisms contained in the seawater pass through a high speed rotating drive unit and a stationary unit, impact, shear force and cavitation destroy the biomechanical structure of aquatic organisms

- The device is multi-tiered with control motor, rotating part and fixed part.

- Re-disintegration into an untreated marine bioinducer circulation through the mid-opening of the septum

- Rotational end tilting design increases the degradation efficiency by introducing a large amount of marine life into the unit of death device

Device technology overview

Impact

In a ship ballast water, a waterborne organism collides with a wall surface of a pipeline, and particles collide, and the biomechanical structure is destroyed by the impact

Shear force

Fluid passing through the pipeline at a rapid flow rate instantaneously breaks down the cells of the aquatic organism due to the shear force acting on the fluid due to the resistance such as speed difference and friction.

Cavitation

Intermittent hyperbaric and ultra-fast fluid pressure differentials cause cavitation and aquatic organisms are destroyed during passage through the device

Specification by processing capacity

| Item | Spec. |

| Capacity | 200 ton/hr |

| Design Temperature | -30 ~ +30°C |

| Operating Pressure | 0 – 2 bar |

| Operating speed | Max. 1800 rpm |

| Seal flushing liquid | Sea water |

We are working on the research and development and commercialization of BWMS pretreatment system in cooperation with Waterpin LTD.